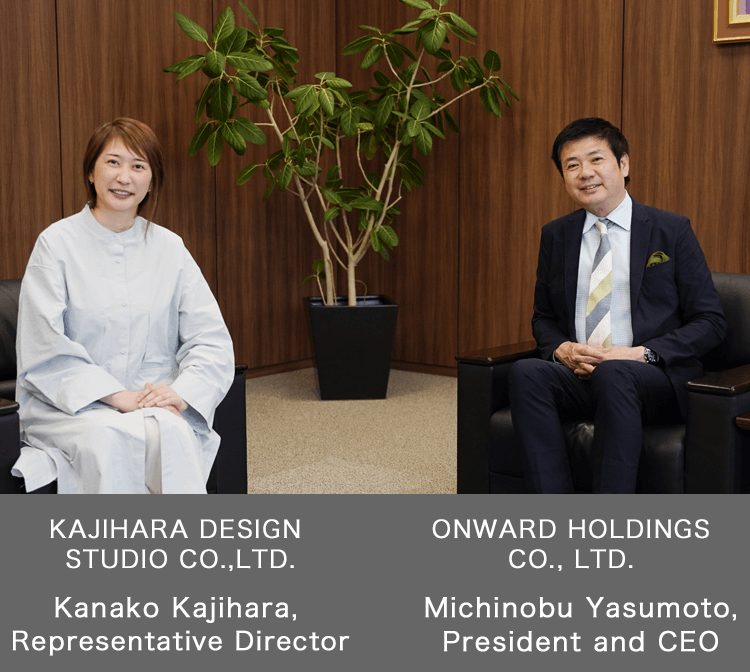

Executive Dialogue on Sustainability

The Onward Group has established the mission statement "enriching and adding color to people's lives while caring for the planet," and aims to promote management that coexists with the Earth. We sat down with Kanako Kajihara, Representative Director of KAJIHARA DESIGN STUDIO CO.,LTD., who is a textile designer with a deep knowledge of sustainability, to speak with our company President and CEO Michinobu Yasumoto about sustainable management.

Sustainable management by all employees, not just nice words

Yasumoto: I feel that the term "sustainable management" has become an indispensable part of corporate management. Unfortunately, in the past few years, the apparel industry has often been cited as an environmentally negative industry, and I think its image has been poor. It is supposed to be an industry that enriches people's lives, but I felt a sense of crisis when it was seen this way. Against this backdrop, in 2021 the Onward Group announced its Mid-to Long-term Management Vision ONWARD VISION 2030 and set "Promote Sustainable Management that Pursues Coexistence with the Environment" as one of the 5 strategies to achieve the 2030 management targets.

Kajihara: In the course of doing much work internationally, I have sensed that the sustainability mindset has become much stronger abroad since 2017. Japan was a little late on this, and I feel that the mindset has changed significantly as a result of COVID-19.

Discarding clothes poses a large energy burden, and my specialty, textiles, also uses water and energy, so I feel the difficulty involved in using resources.

Currently, we are proceeding while discussing environmentally friendly textile development. However, there is no way to predict how quickly it will be communicated to consumers. No matter how much manufacturers change their environment, there is no meaning without the relationship with the people. I think it is very important to think about how to communicate with consumers to establish a relationship that we can think about together.

Yasumoto: If we become a company that must always provide new and good products at low prices to survive, it will inevitably put a strain on sustainable management, such as environmental issues. I think the same is true of the way employees work. The long period of price-driven competition may have had an impact, but it resulted in a way of working that did not allow for a good work-life balance.

Of course, customers' values and ideas will have to also change, but I think it is important to communicate with customers and convey our commitment to our products so that they can understand what we have made, even if it is reflected in the price.

Kajihara: It cannot be communicated one-sidedly. We have to think both ways.

Yasumoto: That's right. It is very important to share the concept of sustainable management with all employees, including those in sales. We need to be in a situation where all employees thinking about it, not just saying it nicely in the form of top management's issues. In particular, the situation has changed since the announcement of ONWARD VISION 2030, so we must always think about what needs to be done and keep doing it. And it would be good if we could share our awareness of sustainability with our customers. The future trends around this matter are very interesting.

Kajihara: We are now in an era where a slow-fashion, individually sales mindset is emerging from the mass production of fast-fashion. In that sense, I think it is important to be able to have a conversation with the customer saying that we will make as much as we want while making a commitment to the customer and hope for it. Therefore, I am also strengthening my ability to convey information about the brands I supervise.

I believe that more and more companies and brands will engage in activities that easily attract empathy by telling the story of how they are made, how they are produced, and what the production process is like.

The apparel industry has a very important role to play in creating a society in which customers can use the products for a long time with love and affection, or send them for reuse or repair with love.

100% garment collection, back to made-to-order business roots

Kajihara: In considering the presence of sustainability, there is much to think about in terms of efforts to avoid waste. The energy consumed by incineration also places a heavy burden on the environment.

Large companies are increasingly conducting clothing collections, but there are so many cases where they say they can get to the collection but find it difficult to discuss what happens after the collection.

Your "Onward Green Campaign" is managed in an integrated manner from collection to post-collection, isn't it? The items are even sold at the Onward Reuse Park. I believe that this kind of recycling and reuse system will be explored in the future society.

Yasumoto: When we launched the Onward Green Campaign in 2009, we had a strong desire to create opportunities for customers to visit our stores and to deepen our relationships with customers. It was right after the collapse of Lehman Brothers, and the economy was in a bad period, but I remember that there were quite a few other companies that started such activities. Each company was having a hard time deciding what to do with the collected clothes, and many companies stopped their activities. We were blessed with good partners and were able to recycle them into work gloves, blankets and solid fuel. It would have been impossible to do it solely within the company. We have also been selling reuse items since 2014.

The problem now is that it's hard to increase the amount of collections. If we try to increase it more than it is now, I don't see the narrative of getting closer to 100% without making additional efforts. There are various ways of looking at this, such as whether it should be completed within our company or whether it would be better if such a system could be established across society as a whole.

Kajihara: Many of our customers also want to help society, but when it comes time to do so, it is not always easy to think about the benefits to themselves.

That is the problem in promoting sustainability. While it may be good for the soul, I think we need to feel closer to the question of whether it is beneficial to our own lives. I think it is necessary to concretize what it is that makes people feel the need for it, along with a realistic and easy-to-understand way to communicate.

Make-to-order production is the first measure to avoid mass production. I believe that companies need to take the initiative in devising ways to communicate and encourage make-to-order production. Your company has been selling custom-made suits and smart factories for a long time.

Yasumoto: This is of course sustainable management, but it is also very important as a management strategy to have a business model that does not leave inventory. Naturally, there is an up-front cost to investing in a factory, but I had a feeling that we would shift to such a business model. About three years ago, we established a smart factory that combines sewing techniques with technology.

Onward Kashiyama originally grew because its founder brought in ready-to-wear clothes at a time when the only suits available were custom-made and people paid three months' salary for a suit, so in that sense, I wonder if the shift to custom-made suits is a return to its roots. That was the norm originally. If it were three months' salary as it used to be, there would be only a limited number of people who would make it, but in today's technologically advanced world, smart factories can provide it from 30,000 yen.

Choosing ways of working in a new age

Kajihara: I feel that the topic of local production for local consumption is getting attention recently. I think many people are starting to become knowledgeable about logistics costs and the energy use associated with them. Rather than going out of their way to sell their products away from the production area, say, in Tokyo, there has been a rapid increase in the number of factories that sell to the local people in the production area and even build communities. The younger generation seems to be particularly interested, and they are expanding their activities from where they can, such as working at a factory in the production area and directly selling their products.

Yasumoto: Now, I think the most central part of the local production for local consumption business is whether the younger generation will feel the future and choose it as their job. For a long time, people used to go to urban centers such as Tokyo and Osaka when it came to finding a job, so it was commonplace to see a concentration of jobs in one area. However, it is difficult to imagine with certainty what kind of different values the younger generation will begin to have in terms of how they work and live in the future.

Kajihara: COVID-19 has led to more people being open to living in rural areas. If factories are confined to the limited concept of only making made-to-order products, people may not take root and quit, but if they can take action by building communities, creating platforms, and developing the ability to create even in factories, I think people will come together.

Yasumoto: You're right. It is also good to, for example, live in a rural area but also have relations with Tokyo, where the head office is located, as you do yourself. I think it would be good if we could choose a lifestyle and way of working that incorporates the best of both worlds, rather than going to extremes such as living only in the city or only in the countryside. I think our Work Style Design initiative, which we have been working on since 2019, is inextricably linked to the fact that we enjoy our lives, which leads us to be able to work with our individuality and to achieve the best results at work.

Kajihara: As society is shifting to one in which a variety of work styles are desirable, we have introduced a system in which experienced workers in their 50s or older can be rehired and can freely choose the number of days they work. We also focus on mental care for people in their 20s and 30s, because that a time with many big life events. It means that there are many people who worry because they have more options to work.

Connecting with the community, together with our partners

Yasumoto: Established in 2016, "Onward Marche" is a collection of delicious gourmet delicacies from all over Japan that shines a light on the high-value content being nurtured in rural areas. There are many things in Japan that we can be proud of, and we started this project with the hope that we could introduce these things to the world. Compared to the United States and China, Japan is a small country, so it is difficult to win in terms of scale. However, even though the scale is small, there are things that are unique and cannot be imitated. Since food products are inevitably directly related to soil and water quality, we started "Onward Marche" because it is not easy to imitate.

CRAHUG, which supports Japanese craftsmanship and for which you serve as director, has the same concept as Onward Marche. The textile industry is derived from agriculture. I had always hoped to do something in the fashion field, which is my main business, so I was able to start in part thanks to my encounter with you.

Kajihara: Domestic mills were accustomed to waiting for orders for contract processing during the textile industry's growth period. But I think such a sense of age ended in the first half of the 2000s. The mindset has changed to one in which we have some special skill or strength and somehow sell what we have made. In addition, many factories are having problems with the change of generation, so we need to strengthen our ability to communicate to the next generation in order to attract their interest, and there is a growing trend to do factory branding. However, there are several problems. Although some of the technologies are already recognized around the world, there is a lack of experience and knowledge in the areas of brand building and commercializing and marketing the products on their own. To solve this problem, we believe that CRAHUG has a significant role to play as a platform for supporting factories.

Yasumoto: We hope to continue to broaden our connections with the community and with craftspeople who are responsible for local manufacturing. Sports are very popular now. I feel that there is a desire for everyone to support their hometown.

Kajihara: I was involved in the launch of a factory brand in Akita called "aiile" through CRAHUG, and I heard that the fundamental reason for wanting to launch the brand was to show people in Akita that "this kind of thing can be done in Akita" through their own efforts, and to encourage and energize the local people. It seems that the business itself was doing well even without taking on the challenge, but I suppose it was still worthwhile to take on the challenge.

Yasumoto: We also started cross-border sales this year. Our goal is to create an image of a business model in which we want to promote and sell unique and inimitable Japanese products to the world, and I would like it to build up your experience little by little. We started with cross-border e-commerce, but the other would be ideal if we could sell our products overseas with partners who understand the CRAHUG initiative.

Kajihara: I feel that the international reputation of things born from Japanese culture is high. The culture of Japanese hospitality and the spirit of Zen are unique sensibilities born from the island nation's worship of nature. In the midst of the world's anxieties in the wake of COVID-19, there is a growing interest in the positive feelings that emerge in the Zen mind, which is the heart and soul of the world. Japanese gardens and tea ceremonies are also popular, and the bonsai, tea utensils, and ceramics that go with them are highly regarded overseas. CRAHUG aims to increase the number of partners who can become fans by carefully communicating the significance of its efforts and the story of each product.

In terms of textile trends, which is my main profession, the selection of manufacturing methods that do not burden the environment and the use of recyclable materials have become major issues. We are in the process of developing one step ahead in the advancement of circular fashion. In order for Japanese textiles to lead the world, we are devising ways to combine specialized techniques and design with an awareness of sustainability. I would like to support the global activities of Japanese production areas by utilizing the overseas experience cultivated up to now. There are many other issues, but I will try to solve them carefully one by one.

Yasumoto: That's right. We would like to share what we are working on and the challenges we are facing not only within the company, but also with our stakeholders and external partners to expand our network. Of course, all employees in the company need to raise their awareness and think about what they should do.

Whether inside or outside the company, inside or outside of Japan, we cannot expand our network without first communicating. We will continue to work with importance placed on communication.

Thank you very much for today.

Profile of Kanako Kajihara,

Representative Director, KAJIHARA DESIGN STUDIO CO.,LTD.

Born in Sapporo City, Hokkaido. Graduated from the Department of Dyeing and Weaving, Faculty of Design, Tama Art University.

Completed her Master's degree in Fashion and Textile Design at the Royal College of Art (RCA) in the UK. As a textile designer, she is involved in the material development of production factories and the global dissemination of Japanese textiles. She works with companies in various fields such as fashion, interior, cars, and architecture, and is also responsible for overseeing branding as a creative director. In the forest of Sapporo, she established "COQ", a complex of shops, dining and hotels, to convey the balance of living with nature in the local area.

Since 2021, she has been the creative director of CRAHUG, a D2C project launched by Onward Digital Lab to support manufacturing in Japan.

References

- ・ Mid-to Long-term Management Vision, ONWARD VISION 2030

- ・ Onward Green Campaign to create a clothing recycling system(in Japanese)

- ・ Made-to-order brand "KASHIYAMA"(in Japanese)

- ・ News release material: Onward's workplace reform project Work Style Design initiatives and results(in Japanese)

- ・ Onward Marche coordinates delicious foods(in Japanese)

- ・ CRAHUG, a D2C project supporting manufacturing in Japan(in Japanese)