Environmentally Friendly Manufacturing

The Onward Group is promoting manufacturing and the online merges with offline-style services, or OMO services that achieve both environmental friendliness and enhanced customer satisfaction and convenience. Our initiatives include expansion of made-to-order production, efficient merchandising by eliminating barriers between physical stores and e-commerce through the integration of inventory data, and development of sustainable products.

Expansion of made-to-order business

We are expanding application of a made-to-order model centering on men's and women's apparel. Production starts upon receipt of orders from customers. We plan to introduce made-to-order for non-clothing items such as bags to minimize excess inventory and waste of materials.

Smart factories for customized made-to-order production

The Onward Group is expanding made-to-order businesses in which it swiftly delivers clothing items carefully crafted to fit customers perfectly based on their orders. Combining cutting-edge technologies with seasoned made-by-hand craftsmanship, the smart factories used for our KASHIYAMA brand eliminate wasteful production.

The KASHIYAMA brand Smart Factories

Drastic Reforms of All Manufacturing Processes to Eliminate Wasteful Production

- Smart factories link data from orders with computer-aided manufacturing processes and use automatic cutting machines to cut cloth more precisely and thereby reduce the portions of cloth that cannot be used. In addition, these factories utilize automatic ordering systems for incidental items (buttons, lining, etc.) to ensure appropriate inventory levels.

- We manage products with radio frequency identification (RFID) tags and hanger systems while using tablets for process management to swiftly produce items customized based on customers' requests.

-

Fabric automation management

-

Management by RFID and hanger system

-

Sewing of customized orders quickly and carefully

An Efficient Distribution System

- In our made-to-order businesses, we take wasteful warehouses out of the equation and deliver products directly from factories to customers.

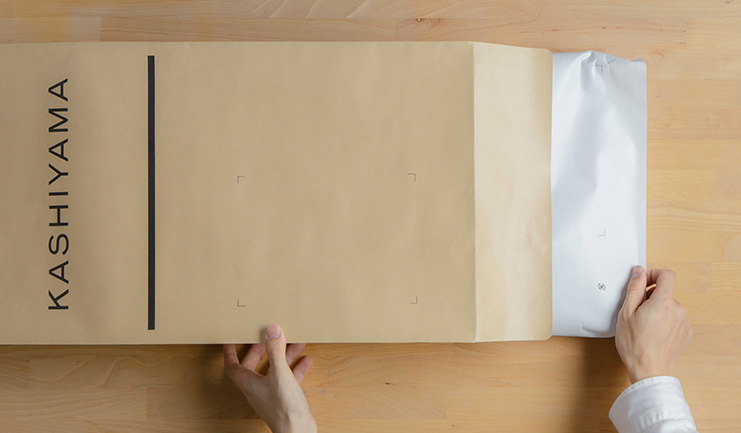

- We use PACK-RUNNER compressed and sealed packages to help substantially save space in logistics vehicles.

- We have also changed our delivery packages from cardboard boxes to paper packages. This approach makes our packages even more environmentally friendly and compact.

-

PACK-RUNNER

-

Paper delivery package

-

Environmentally friendly, compact package

Other Environmental and Workstyle Initiatives

- The Onward Group is advancing paperless process initiatives to conserve paper resources. For example, we have abolished paper order slips, instead choosing to process orders via tablets and send order information in data form. Similarly, we transitioned from paper to digital customer records.

- We have also replaced certain lighting fixtures with LED lighting to conserve energy.

-

LED lighting on the sewing line

-

Cafeteria, a place for employees to relax

-

Cafeteria

High-quality garments with an excellent fit at low prices and quick delivery. Deploying our factory-to-customer (F2C) business model without inventory realized through drastic reform of the entire production process, we are the pacesetter in a new era in which anyone can have clothing that fits just right.

-

the KASHIYAMA brand Smart Factory Movie (in Japanese)

-

the KASHIYAMA brand website (in Japanese)

Integration of inventory data encompassing physical stores, e-commerce, and warehouses

Through integration of inventory data encompassing physical stores, e-commerce, and warehouses, we have streamlined merchandising, eliminating the barriers between these elements of the business. We are promoting OMO services to enrich the customer experience with the aim of further enhancing customer satisfaction.

We are creating venues where customers can enjoy the maximum benefits of both online and offline experiences through OMO stores offering the services of physical stores combined with those of online stores. At ONWARD CROSSET STORE/SELECT stores, customers can try on and purchase items not only from the stock at physical stores but also items available online, which they can have delivered to the store of their choice for them to try on and consider purchasing. In addition, these OMO stores have sustainability in mind. They offer repair & maintenance services and participate in the Onward Green Campaign to collect used Onward Group apparel items from customers so that they can be reused or recycled to the greatest degree possible. Going forward, we plan to open more OMO stores.

Sustainable Manufacturing

steppi by UNFILO, a New Line of High-performance Sustainable Shoes

Onward Kashiyama launched steppi by UNFILO, a new line of environmentally friendly, high-performance sustainable shoes, in spring 2022 under the UNFILO brand. Sharing the philosophy of the UNFILO brand that aspires to fulfill the needs of the era in terms of both functionality and fashion, the development team aimed to propose shoes for daily use that are washable, light, and gentle on your feet, achieving the goal after about two years of development.

Lightweight

Each shoe of a pair of basic flats weighs just 120 grams, as light as about two eggs. The secrets are the one-piece knitted upper and the outsole made of foam. Lightweight recycled polyester yarn is used to create a flexible knit, eliminating the need for backing or core material. The outsole is light and has cushioning comparable to running shoes yet with the neatness of flats, achieving a perfect balance.

Sustainable

Made of polyester yarn derived from recycled PET bottles and plastic waste. Recycled materials are also used to some extent for the outsole and insole. In addition, the shoe box is eliminated, resulting in reduction of CO2 emissions from transportation. The original shopping bag available with charge is made of sustainable materials and can also be used as a laundry net.

Water-repellent

Since the yarn itself is treated to repel water, the shoes repel water and typical dirt can be wiped off. In addition, the sewing thread is also treated to repel water. So, penetration of water via stiches is prevented, too.

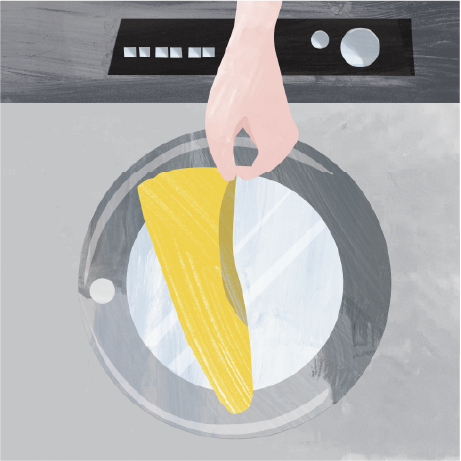

Washable

If you feel the shoes could do with a thorough clean, remove the insoles, put the shoes and the insoles together in a laundry net, and put it in the washing machine. Select the handwash cycle. Ordinary alkaline laundry detergent can be used for washing the shoes. Try our original shopping bag available with charge that can also be used as a laundry net. After washing, hang the laundry net with the shoes in it on a hook to dry in the shade.

"product,"an Organic Wildcrafted Haircare and Skincare Brand

The "product" brand is a line of organic wildcrafted haircare and skincare goods produced by KOKOBUY that debuted in 2007 in California.

To ensure superior quality and better performance of all "product" goods, plant-derived natural ingredients extracted and refined using state-of-the-art technology are used.

In pursuit of a sustainable society, we are committed to reducing our environmental and societal impacts by dispensing with excessive packaging, continuing to improve transportation efficiency, and using recyclable containers made from recycled materials.

As a brand aspiring to be loved forever, all "product" goods will be sustainable, offering functionality and environmental performance without compromise.

Chacott COSMETICS Produced by Chacott, a Ballet/Dance Goods Manufacturer

In April 2021, Chacott reinvented its line of cosmetics for professional artists performing on stage, originally introduced in 1997, relaunching it as the Chacott COSMETICS line. In revising ingredients and raw materials, in addition to enhanced safety and minimizing the burden on the skin, Chacott focused on sustainability to minimize the societal and environmental impacts, and adopted environmentally friendly materials for packaging.

- ● Vigorous use of plant-based resources (biomass)

- ● Endorsement of various initiatives by adopting fair-trade materials

・ Initiatives of BASF of Germany supporting women in Morocco involved in sustainable production of argan oil

・ Initiatives of All Organic Trading of Germany supporting women in Burkina Faso (West Africa) involved in production of raw shea butter - ● Non-chemical formula, eliminating the use of ultraviolet absorbers, to minimize the environmental impact

- ● Use of bagasse, a material recycled from waste sugar cane, for paper packaging

- ● Use of paper certified by the Forest Stewardship Council (FSC)

- ● Green Printing-certified printing (environmentally friendly printing)